Small format packing collaboration

In recycling, it’s often the little things that get overlooked. And there are a lot of little things: An estimated 30-40% of items smaller than three inches found in glass recycling streams are rejected at the MRF or in secondary processing. Capturing these smaller format packaging items will require breaking down silos to work beyond a single commodity focus.

“The glass industry cannot address this alone,” said Rebecca Thomas, Government Affairs and Sustainability Associate, Glass Packaging Institute (GPI). “Collaborating throughout the recycling value chain is critical for circular glass solutions, as well as keeping small format packaging out of landfills.”

The Glass Packaging Institute announced formation of the Small Format Coalition in June 2025 as a cross-sector initiative uniting brand packaging, material processing, and the recycling value chain to improve the recovery of small format materials from the recycling system. To achieve their mission, collaboration with diverse founding members is essential. Founding organizations were GPI, Nespresso, Colgate-Palmolive, ReMA, Encina, Sibelco, The Recycling Partnership, Sol de Janeiro, Mars, Steinert, TOMRA and Nestlé.

Forgotten Gold in the Glass

For far too long, the glass pile in single-stream MRFs without proper cleaning equipment has been synonymous with a “residue” pile. Scattered among shards of mixed glass are small items like aluminum caps, plastic tubes and caps and small paper wrappers and cartons. While broken glass can be recycled, an additional step of beneficiation or secondary processing is required to remove the small format materials and non-glass residue (NGR). Most of these small format materials are destined for disposal while the recoverable glass is sorted by color.

Taking some additional steps to sort the residual glass pile at the MRF is economical. MRFs with advanced clean-up systems can provide more opportunities to capture cleaner glass and find recycling solutions for the smaller materials. These systems do not have to be expensive, but not all MRFs are prime candidates for such systems given volume and end-market limitations.

“It’s not a ‘one-size-fits-all’ approach, but rather a cross-industry effort to deliver feasible, scalable solutions that benefit the entire recycling recovery ecosystem in the US,” says Amy Uong, Senior Recycling Manager at Nespresso USA, a founding partner of the Coalition. “The goal with the [Small Format] Coalition is to help tip the economics in favor of recovering small formats through funding different scenarios and to provide insights into these strategies.”

What Does Action Look Like?

The Coalition will prioritize ways to sort small format materials by retrofitting existing facilities, recirculating material, and adopting best practices for designing new MRF structures to bolster recovery. The organization’s goal is to provide actionable investment solutions that are scalable across multiple markets.

On its menu of possible investments, the Coalition will work with MRFs and equipment operators to explore their primary and secondary sorting levels to optimize the MRF’s existing technology systems. Each MRF is unique; most will likely only require layout reconfiguration and simple modifications to the glass screens to catch recoverable small format items.

Equipment may be specific to glass, like glass breakers, trommels and debris screens on a primary level. Size separation for items over two inches involves using trommels and vibratory decks to sort lightweight material like small-shredded paper or fines. Vacuum systems with air knives, zig-zag air separation, air chambers, or blowers can separate ceramic, stone, or small plastic. Metal removal is done with magnetic head pulleys and eddy currents. There are options with optical sorters in some cases.

“We can mitigate some of the burdens that the secondary glass processors would have by sorting for those materials, and open up markets for recycling small materials,” said Uong.

The Coalition looks at its mission as an end-to-end solution. The goal of the work is to spur new end markets for small format materials, and then brands will also commit to purchasing recycled content.

EPR Driving Innovation

Regulatory pressures invite innovation to recover more recyclables. Extended Producer Responsibility (EPR) regulations have recently passed in seven US states, so far. The Small Format Coalition plans to commence its first infrastructure investment in one of those states with EPR, providing the potential for scalability.

“EPR provides an opportunity to accelerate multi-industry dialogue and collaborations such as this,” said Scott DeFife, president of GPI and a Colorado EPR Advisory Board Member. “GPI raised the need for infrastructure investment for clean-up on the MRF level during the EPR needs assessment. This is necessary, if we are to be transparent about recycling as a whole, but can also reduce the producer responsibility organization expense.”

Under EPR laws, packaging producers are required to meet recyclability or compostability requirements for the packaging they produce. To be in compliance with EPR laws, packaging producers will need solutions for many under-recycled items like small format materials and glass packaging. Addressing multi-component and multi-material items, like plastic pumps with metal springs or low-market items like film or black plastics will be necessary. To solve this barrier, brands and manufacturers may look at product redesign for recoverability.

Benefit for MRFs and Markets

Glass bottles and containers have been hallmarks of recycling programs since the beginning. Some single-stream MRFs have bemoaned glass acceptance in the past because, unlike other recycling commodities, glass breaks when compacted. That breakable tendency mixed in single-stream recycling further complicates its recovery. Broken glass is recyclable; in fact, glass is intentionally broken in the MRF as a method of sortation.

MRFs express frustration with small items clogging screens and conveyors, which often result in delays on sorting lines and production efficiency. The lost throughput means fewer tons get recycled, driving up the cost per ton for MRFs. To better understand the opportunities to capture small format materials, GPI commissioned a study of the contents of the glass stream from eight total MRFs in two different states.

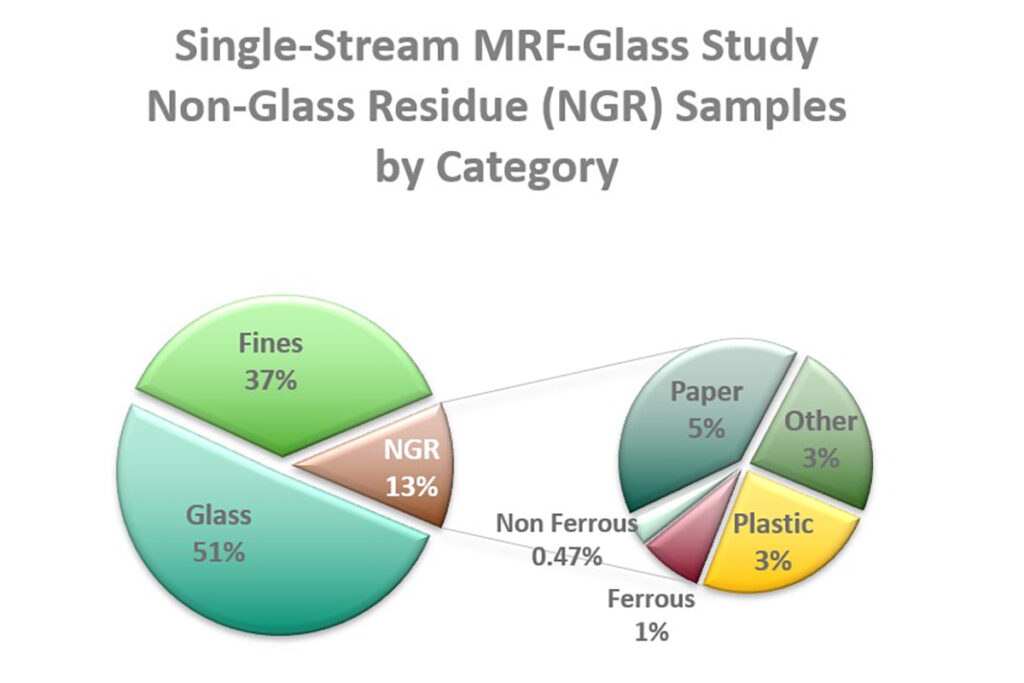

Results from four MRFs in one state found 13% non-glass residue (NGR) by weight in the glass stream, including 5% paper, 3% mixed plastics and less than 1% metals (Figure 1, below). Glass samples from the four MRFs in the second state found almost 20% NGR with a similar commodity breakdown, although with a larger percentage of metals. The data indicates the opportunity by commodity if these items were positively captured before making it to the glass supply chain.

“We’ve seen how with the right tweaks and creative applications of existing technologies, recycling facilities have the potential to significantly improve material recovery, reduce waste, and redirect valuable plastics from landfills to the secondary commodities market,” said Tom Outerbridge, President, Circular Services Recycling.

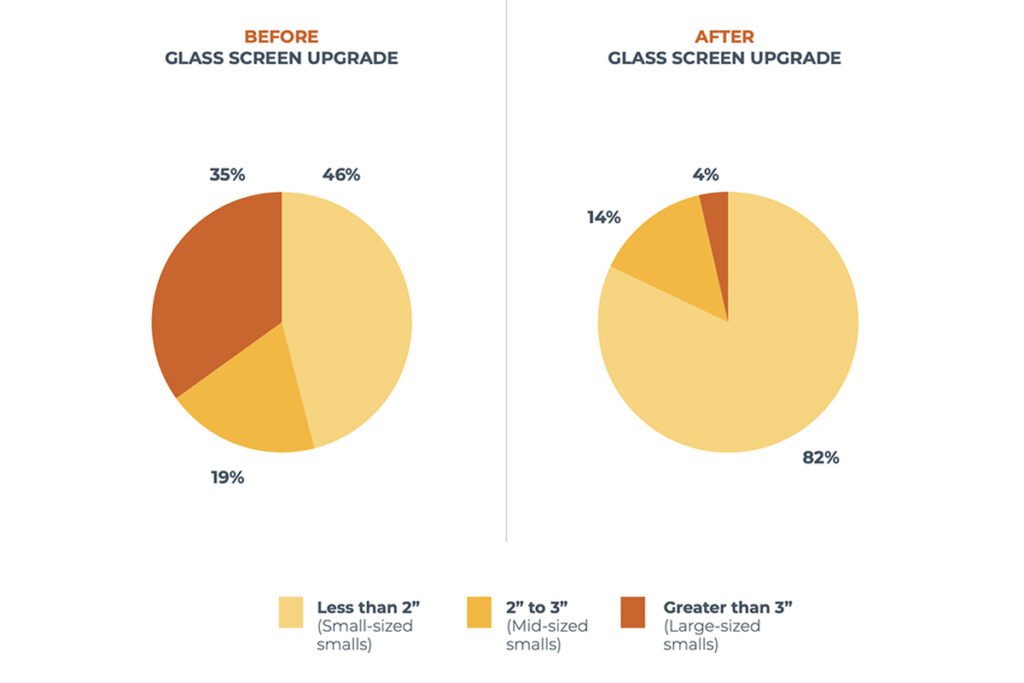

According to research conducted by Closed Loop Partners’ (CLP) Center for the Circular Economy, upgrades to glass screens to keep packaging between two-and-three inches – like PET, aluminum containers and other materials – from leaving the container line, and out of the glass stream led to cleaner glass and optimized sortation. The Center’s intervention at one US MRF measured that upgrading the glass screen resulted in an approximately 67% reduction in mid-to-large size “small” plastic contamination in the glass stream. Figure 2, below, shows percent of contamination at various screen sizes contaminating the glass stream before and after the upgrade. Maintaining upstream equipment like screens is a best practice and key to operating a high-performing facility.

“Our in-market research on small format packaging from the past three years identified a clear pathway to recover tens of thousands of tons of valuable small materials to meet the growing demand for recycled materials,” said Sarah Pamplona Santos, Senior Project Director at CLP’s Center for the Circular Economy. “We recommend new, innovative ways of configuring a set of existing equipment at MRFs to recover more small format material. Collaboration across the value chain is critical to driving systems change and has been a key part of the Center’s approach.”

Rumpke’s newest materials recovery facility in Columbus, Ohio, reports that the latest size-sorting technology is resulting in minimal contamination of midsize or large, small format materials in the glass stream. These larger materials are successfully sorted within the main MRF and directed into appropriate bales. Plastic contamination of the glass stream was mainly bottle caps or broken plastic fragments, rather than larger items like travel-size bottles or deodorants.

Currently, markets are limited for small format packaging due to the inability to capture and measure due to size, weight, or commodity density. This leads to increased residue or lower value for glass at a secondary processor. There are opportunities for some small formats to be intentionally integrated into current bales of recycled materials sandwiched between larger items. For plastics, both mechanical and chemical (molecular) recyclers have shown interest in small format materials, creating potential end markets.

Possibilities for Paper

Small format fiber-based packaging that makes it to the glass pile will likely not be sorted properly to be recovered in current systems. As an early adopter of recycling collaboration efforts, Tetra Pak, helped co-found the Carton Council in 2008, a coalition that expands recycling of used food and beverage cartons.

“While Tetra Pak currently has no small format packaging in the US and Canada, we are committed to creating a more sustainable future,” said Jason Pelz, vice president of sustainability for Tetra Pak-U.S. and Canada. “To accomplish this, we collaborate with organizations that seek actionable solutions to waste.”

The future for glass recycling and solutions to recover small format items is promising. While there is no silver bullet for every MRF and secondary glass processor, willing collaborators working across the various material types and industries are laying the foundation for circularity and bolstering new recycling markets. Programs and organizations uniting to resolve past gaps in recycling are writing a new chapter in sustainable, circular packaging recovery.